- support

- info@evidentic.com

- +49 (0) 30 959 99 8831

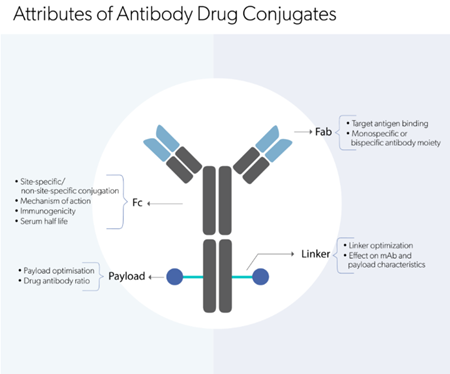

Biologics such as monoclonal antibodies and therapeutic proteins are complex molecules produced by recombinant methods and are delineated by the physical, chemical, biological, or microbiological properties that define them. These characteristics of Biologics are known as quality attributes of the biologic, and they vary depending on the post-translational modifications that take place in the cellular environment or during the multi-step manufacturing process. However, among the many quality attributes of Biologics, some key attributes determine the product’s efficacy or safety, which are known as critical quality attributes (CQAs). Identifying these CQAs is key to implementing quality by design (QbD) for product and process development (Figure 1).

As per the QbD approach, it is also important to integrate the critical material attributes (CMAs) and critical process parameters (CPPs) into the development pipeline to ensure final biologic drug product with the desired CQAs. Furthermore, appropriate risk assessment and control strategies for routine monitoring of CQAs need to be designed during the downstream manufacturing processes of biologics.

Primarily, depending on the quality target product profile (QTPP) of the biologic product, potential CQAs (pCQAs) are identified and used to guide biologic product and manufacturing process development. For example, if Fc effector function is responsible for the mechanism of action (MoA), certain Fc glycosylation variants may need to be considered pCQAs. So as to be included on the pCQA list, an Fc variant may be identified by specific modification studies (eg., forced degradation) during method characterization or isolated from manufactured materials. The pCQAs list expands as additional product and process knowledge are gained over time with extensive analytical characterization, animal studies, and expanded clinical research. A comprehensive list of pCQAs is classified to establish linkages between specific product attributes of the biotherapeutic to the expected clinical performance. While the relationship of each pCQA to clinical outcomes cannot be directly studied, the potential patient impact can be inferred from analytical and biological characterization, including structure-function studies. In the case of Biologics, categorizing attributes into groups such as product-specific variants, process-related impurities, and obligatory CQAs eases and guides the criticality assessment approach.

Quality risk management guideline outlined by ICH Q9 can be used to rank the list of potential CQAs. The relevant CQAs can thereby be identified by an iterative process of quality risk management and experimentation that determines how their variation can impact the quality of the biologics (Figure 3).

Thus, the criticality of pCQAs is assessed using a risk ranking and filtering approach with respect to their impact on bioactivity, pharmacokinetics (PK), pharmacodynamics (PD), immunogenicity, and safety. Moreover, product–specific information is gained from clinical or non-clinical observations, analytical and biological characterization, studies with related molecules, platform-molecule knowledge, and published literature.

Although, variations occur in the exact approach and specific scoring tools implemented by different groups, a general a scoring system is employed based on two factors: impact and uncertainty. The research group consists of expertise from multiple disciplines, and the team evaluates each product quality attribute and its impact on potential impact on safety and efficacy as well as the relevance and uncertainty of the available information/prior knowledge. The scoring system consists of different scales with maximum limit of 5 levels where impact and uncertainty factors are scored independently. Yet, the higher weightage is allotted to the impact factor highlighting its higher importance. Subsequently, the two values are then multiplied to obtain a risk score for each product quality attribute. The final result is a listing of quality attributes along a criticality continuum. Such an assessment is performed at prime stages during process development, with studies designed to improve product knowledge and drive down the uncertainty. Ultimately, objective of such chosen scoring system is to ensure consistency of the assessment approach throughout the product life-cycle.

The product attributes are categorized into three groups for analysis during the early-stage product characterization. The risk ranking and filtering approach for CQA identification is mainly applied to product-specific and process-related pCQAs:

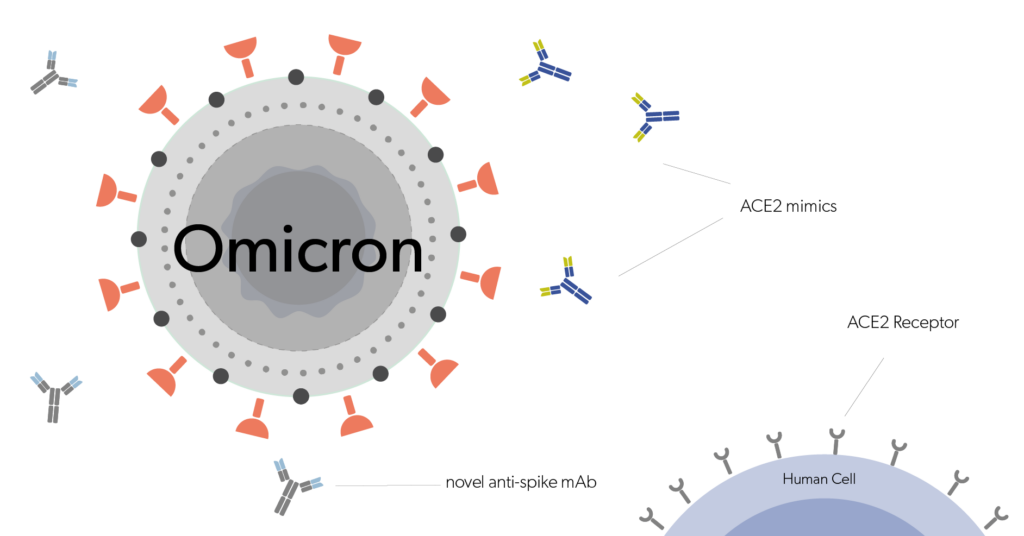

Knowledge can be applied from existing products or related products during the early phase development of new therapeutic molecules such as monoclonal antibodies, bispecifics or fusion proteins. For example, Fc-fusion proteins have structural homology to the IgG1-Fc region of established mAb therapeutic proteins. In such cases, related proteins can be used as a reference to benchmark specific attributes and therefore help identify the quality target product profile.

However, for the development of biosimilars, it is critical to evaluate the reference drug product in depth. In order to categorize the QTPP, several batches and ages (shelf life) of the reference drug must be characterized to obtain information regarding the various quality attributes and their acceptable limits or range. Several analytical methods are used to delineate the quality attributes and based on their probable impact on biological activity, potency and clinical safety, a criticality score is given. Hence, the CQAs are selected after assessing the biological effector functions, in-vivo PK/PD, safety, and efficacy. Apart from mapping the structure and structure-activity relationship of the originator molecule, biosimilar development must also consider the formulation, host-cell protein or endotoxin levels and the presentation of the reference biologic.

Due to the obvious changes in the biosimilar manufacturing process, variations in specific quality attributes are accepted for regulatory submission. However, the CQAs of the biosimilar candidate must be within a specified range, compared to the original reference drug, to obtain biosimilarity approval.

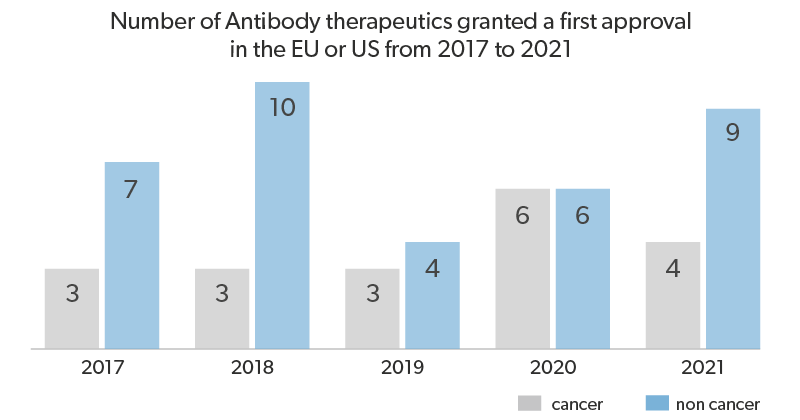

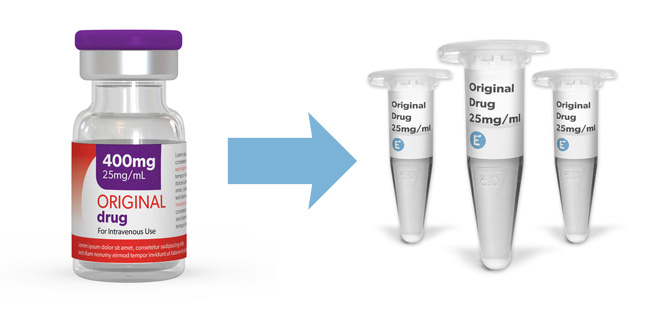

Evidentic is your sourcing specialist who provides aliquots approved biologic drugs as research consumables. Our product portfolio comprises various biotherapeutic platform molecules, including mAbs, fusion proteins, ADCs, bispecifics and other biologics that can be used for analytical, in-vitro and in-vivo research purposes. Our aliquots contain the original formulation (buffer and concentration), as we repackage the content of the original vial into small tubes – aliquots. We source any EU approved molecule.

Find out more about clinical-grade molecules

Evidentic GmbH

Martin-Buber-Str. 10

14163 Berlin